Recognizing the Numerous Kinds Of Welding Techniques and Services Readily Available

Introduction of Welding Strategies

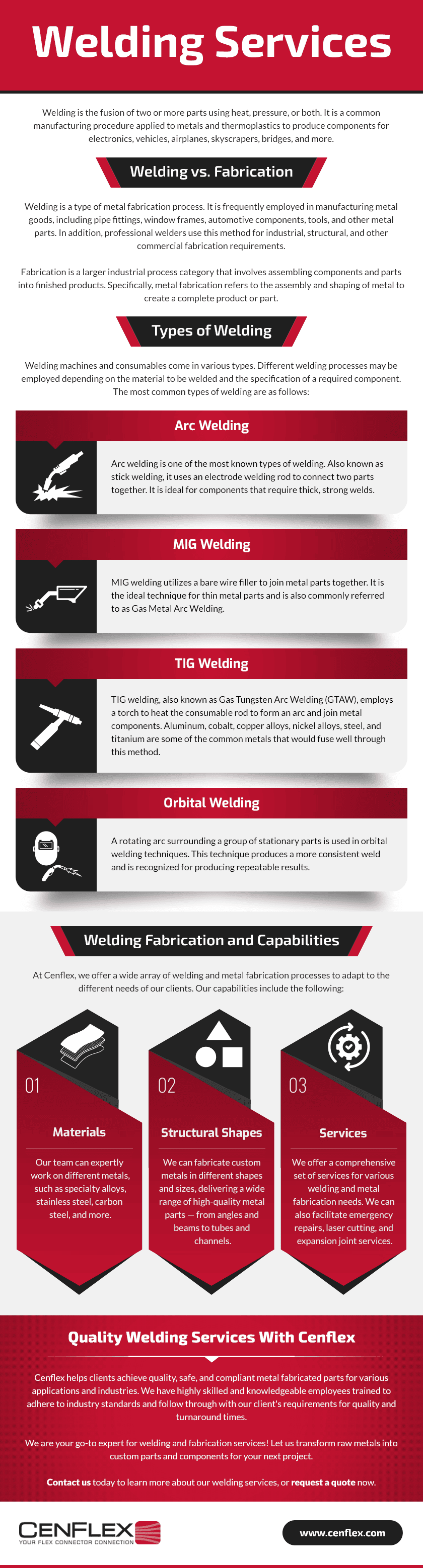

Welding techniques encompass a diverse variety of methods made use of to sign up with materials together completely. One typical approach is arc welding, which entails creating an electric arc in between the base and an electrode material to thaw and fuse them together. This method is functional and can be used with numerous steels, making it among one of the most widely utilized welding processes.

Additionally, TIG welding, or Gas Tungsten Arc Welding (GTAW), is a accurate and tidy welding approach that uses a non-consumable tungsten electrode to produce the weld. TIG welding is generally utilized for thinner products and supplies exceptional control over the welding process. On the whole, recognizing these different welding methods is essential for choosing the most ideal approach for various tasks.

Generally Utilized Welding Methods

An array of generally made use of approaches are utilized in the area of welding to successfully sign up with products with each other. Among one of the most commonly made use of strategies is Gas Metal Arc Welding (GMAW), also understood as MIG welding. This technique utilizes a cord electrode that is fed via a welding gun, together with a securing gas to shield the weld from contaminants airborne. Another typical method is Shielded Metal Arc Welding (SMAW), or stick welding, which utilizes a flux-coated electrode to produce the weld. Tungsten Inert Gas (TIG) welding is preferred for its accuracy and versatility, using a non-consumable tungsten electrode to generate the weld. Flux-Cored Arc Welding (FCAW) is typically used in industrial settings due to its high welding rate and transportability. Furthermore, Submerged Arc Welding (SAW) is excellent for creating deep welds on thick materials. These typically used welding methods deal with different needs and materials, providing alternatives for various welding applications.

Advanced Welding Solutions

Building upon the foundation of frequently utilized welding techniques, the realm of advanced welding solutions incorporates sophisticated methods and technologies that press the borders of accuracy and efficiency in product signing up with procedures. Advanced welding solutions usually entail specialized methods such as laser welding, electron light beam welding, and friction mix welding. Friction mix welding, a solid-state joining process, allows the welding of products that are testing to fuse using traditional approaches, like aluminum and copper.

Specialized Welding Techniques

One more specialized welding strategy is laser light beam welding, where an extremely concentrated beam is made use of to join metals with very little heat-affected areas and distortion. This method is commonly utilized in markets requiring high dig this precision and sanitation, such as electronics and medical device production. In addition, explosive welding is a special technique that uses controlled nitroglycerins to bond dissimilar steels with each other, producing strong and trustworthy joints. These specialized welding strategies showcase the diversity and advancement existing in the area of welding, offering remedies for a wide variety of industrial applications.

Selecting the Right Welding Refine

With various welding techniques readily available, it is crucial to consider variables such as the type of metal, density, joint style, and desired end outcome when choosing the best welding process. Amongst the common welding techniques are Gas Metal Arc Welding (GMAW), Protected Metal Arc Welding (SMAW), Gas Tungsten Arc Welding (GTAW), and Flux-Cored Arc Welding (FCAW) GMAW, also known as MIG welding, is suitable for welding slim to thick metals and is functional in various placements.

Final Thought

To conclude, comprehending the numerous kinds of welding methods and services available is essential for Get More Info picking the right technique for a details job. By knowing the generally utilized welding approaches, advanced welding solutions, and specialized strategies, individuals can make enlightened decisions to guarantee the success of their welding tasks. It is very important to take into consideration elements such as products, task requirements, YOURURL.com and budget plan when picking the most suitable welding procedure.

From typical techniques like stick welding to cutting-edge processes such as laser welding, the globe of welding offers a plethora of options for signing up with steels together.Furthermore, TIG welding, or Gas Tungsten Arc Welding (GTAW), is a tidy and precise welding approach that utilizes a non-consumable tungsten electrode to produce the weld. Advanced welding services commonly include specialized methods such as laser welding, electron beam of light welding, and rubbing mix welding. Amongst the typical welding techniques are Gas Metal Arc Welding (GMAW), Shielded Metal Arc Welding (SMAW), Gas Tungsten Arc Welding (GTAW), and Flux-Cored Arc Welding (FCAW) By being conscious of the frequently utilized welding techniques, progressed welding services, and specialized techniques, people can make educated choices to make sure the success of their welding projects.